Vietnam De Licacy

Vietnam offers good prospects for textiles industry, and has complete brands supply chain. Therefore, De Licacy invested more than 33 million US dollars in Vietnam in past 2 years, and it is expected that the total investment amount will be up to 66 million US dollars for building a consistent production process from fabric weaving, dyeing, to garment manufacturing.

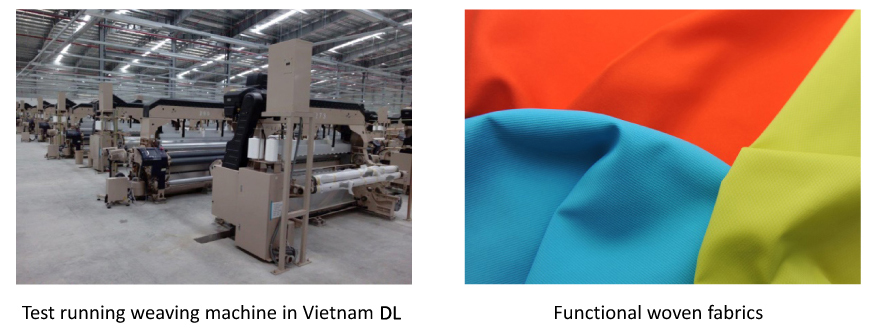

De Licacy Industrial Co., Ltd. was found in 1982 in Taiwan, focusing on research and development. De Licacy’s R&D team collects the latest information about functional textile from raw materials to processing technology and manufacturing. The company is a well-established and experienced manufacturer in Taiwan for more than 30 years with fully streamlined operation from yarn spinning, fabric weaving, dyeing, and setting. De Licacy specializes in producing high quality P/D & Y/D functional woven fabrics. By upholding "Diligence, Research, Friendliness, and Honesty" as business philosophy, De Licacy collaborates with its long-term customers to produce a diversity of refined products that sell all around the world.

De Licacy’s fabric brand, DELINNO, is developed with both functional and aesthetic value to present the newest textile trends. DELINNO focuses on innovation, technology, and fashion, creating materials used in outdoors & sports, fashion & casual, interior textiles areas. The revenue percentage of outdoors & sports is at 65%, fashion & casual 10%, and interior textiles 25%. De Licacy’s customers are mainly brands from the US, Europe, and Japan, including Under Armour (last year revenue percentage is 20%), Adidas (last year revenue percentage is 12%-13%), Uniqlo (last year revenue percentage is 7%-8%), and Puma (last year revenue percentage is 3%-5%), etc.

Starting from 2015, De Licacy has a three-year factory building plan in Binh Duong, Vietnam. The size of this production base is 23ha. Besides fabric weaving and dyeing, there will be garment manufacturing factory in the production base. The building plan is divided into three processes. The first process is completing plant construction, stationing equipment and personnel, and starting fabric operation. The second and the third process are not only upgrading production capacity, but also building garment factory. It is planned to manufacture garments in 2018.

De Licacy’s consistent production process investment plans to make Vietnam as main production base. The core products of De Licacy will be expanded from functional fabrics to garments. This integrates all relative resources to provide customers one-stop-shopping service that can develop products from fabrics to garments.