De Licacy is well known for innovation and design capabilities. By applying capability, hundreds of new qualities are developed monthly to share the newest textile trend to our business partners.

SCORLL DOWN

De Licacy's fabric mill is located in Xinshi District, Tainan. The factory covers an area of about 6,050 square meters and serves as a vertical mill for yarn twisting, fabric weaving, and dyeing to consistently provide high-quality finished products. The factory is equipped with false-twist, coring, twist-yarn machines, which enable to produce various kinds of yarns for color-rich fabrics.

De Licacy is good at producing stretch yarns for stretch fabrics.

De Licacy also owns soft winders and warping machines to provide beam dyeing and pack dyeing for synthetic fabrics, staple fabrics, or blended fabrics. Color yarned can be dyed in the factory to produce yarn-dyed in rich variety. A large number of water jet looms, air jet looms, and Rapier looms can reach monthly capacity of P/D fabric in 4 million yards, and Y/D fabric in 2 million yards. In order to ensure the quality of fabrics, there is various finish equipment for synthetic fabrics, staple fabrics, or blended fabrics. In addition, extra finish machines in De Licacy including coating, lamination, and bonding, provide fabrics with highly valuable functions.

.jpg) The production base of Vietnam De Licacy is 23 ha, located in Bau Bang Industrial Zone, Binh Duong Province, Vietnam. Starting from 2015, De Licacy has a three-year factory building plan. The first phase of production finished in the first half of 2017 that completed factory

The production base of Vietnam De Licacy is 23 ha, located in Bau Bang Industrial Zone, Binh Duong Province, Vietnam. Starting from 2015, De Licacy has a three-year factory building plan. The first phase of production finished in the first half of 2017 that completed factory

construction, stationed equipment and personnel, and started to manufacture. The third phase will be finished by 2019. Vietnam De Licacy is planned for yarn twisting, fabric weaving, dyeing, and extra finishing, and even planned further streamlining to garment making, building a one-stop production base for manufacturing fabric and garment in the future. This provides integration for resources and service of quick responding to customers in order to meet their needs and create more product value.

Surrounded by green plants outside the large windows, De Licacy’s Taipei Sales Office is known for its spacious and bright working environment. A large showroom is established to present various kinds of the newest development in fabric hangers and end-use forms, such as garments and sofas. A number of comfortable meeting rooms are also provided for private and business purposes.

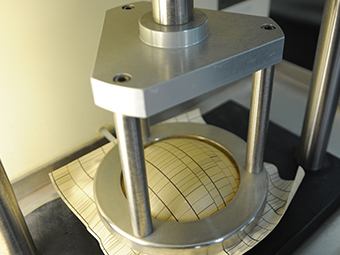

De Licacy R&D team is well known for its innovation and design capabilities. We collect the latest information and trend from fibers, yarns, materials, and colors to develop related production process and dyeing technologies, turning these materials into products matching up with the newest market trends, and even leading the material trends.

De Licacy R&D Center is set as an independent institution, focusing on long-term R&D deployment and patent applications. It also collaborates with Taiwan’s academic and research institutions to create more performance driven fabrics and environment-friendly products.

De Licacy sets up Environmental Protection Department at head office to integrate all the activities regarding industrial safety and environmental related issues. Measures relevant to resource conservation, energy efficiency, carbon reduction, employee safety, and other aspects of green products are designed, adopted, and promoted. Efforts to fulfill our social responsibility as a sustainable green business are exerted without any reservation.

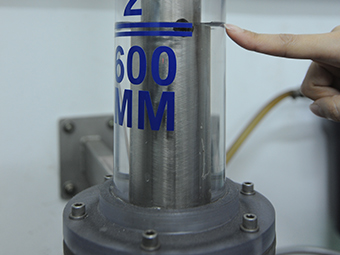

At the beginning of factory construction, De Licacy has initiatively adopted environmentally friendly technologies by investing more than USD 65 million in equipment for waste reduction and pollution prevention. Areas used to accommodate the related equipment cover about 515 square meters, which is about 10% of the total land space of the factory. The two sets of sewage treatment equipment can purify and recycle used water from the production processes before it flows out of the factory to minimize impacts on the environment. Waste-management measures are also taken to classify and to recycle energy and resources. Various projects have been undertaken with an objective to reduce carbon emissions. We have developed low-liquor ratio dyeing machines and low-temperature dyeing and shaping materials and processes to reduce energy consumption. The green vegetation is grown near the factory to lower surrounding temperatures and to reduce the need to use air conditioning. We have also designed the factory building that natural light can come in to reduce power consumption for lighting. We will continue to design and implement related measures to move towards the goal to reduce more carbon emission.